Another build season is behind us. Before and after bagging pictures attached.

Another build season is behind us. Before and after bagging pictures attached.

This year’s game is Power Up. Smaller team this year, but enthusiastic as always. We picked up our Kit Of Parts at LIU on kick-off where we ran into friends. [Hi Suman!]

Busy testing climb ideas while waiting for our CNC Mill to be delivered.

Missed the first round of FirstChoice, but we’re hoping for the best in the second round.

Team 1635 not only builds robots for international high school competitions but also to help develop an interest for engineering in young children. On April 28 a few of the members from the team volunteered to lead an activity at AllianceBernstein for its Take Your Child to Work Day event. Here the team members taught basics of mechanical engineering, electrical engineering and programming. We worked on a basic assembly of a car module, amping it up with the usage of ultrasonic sensors. This allowed for the car to turn when it detected the distance between it and a barrier via soundwaves. It was a great turn out and it became evident that the children were intrigued as they asked multiple questions all pertaining to engineering. We hope to do this again next year in order to further promote robotics.

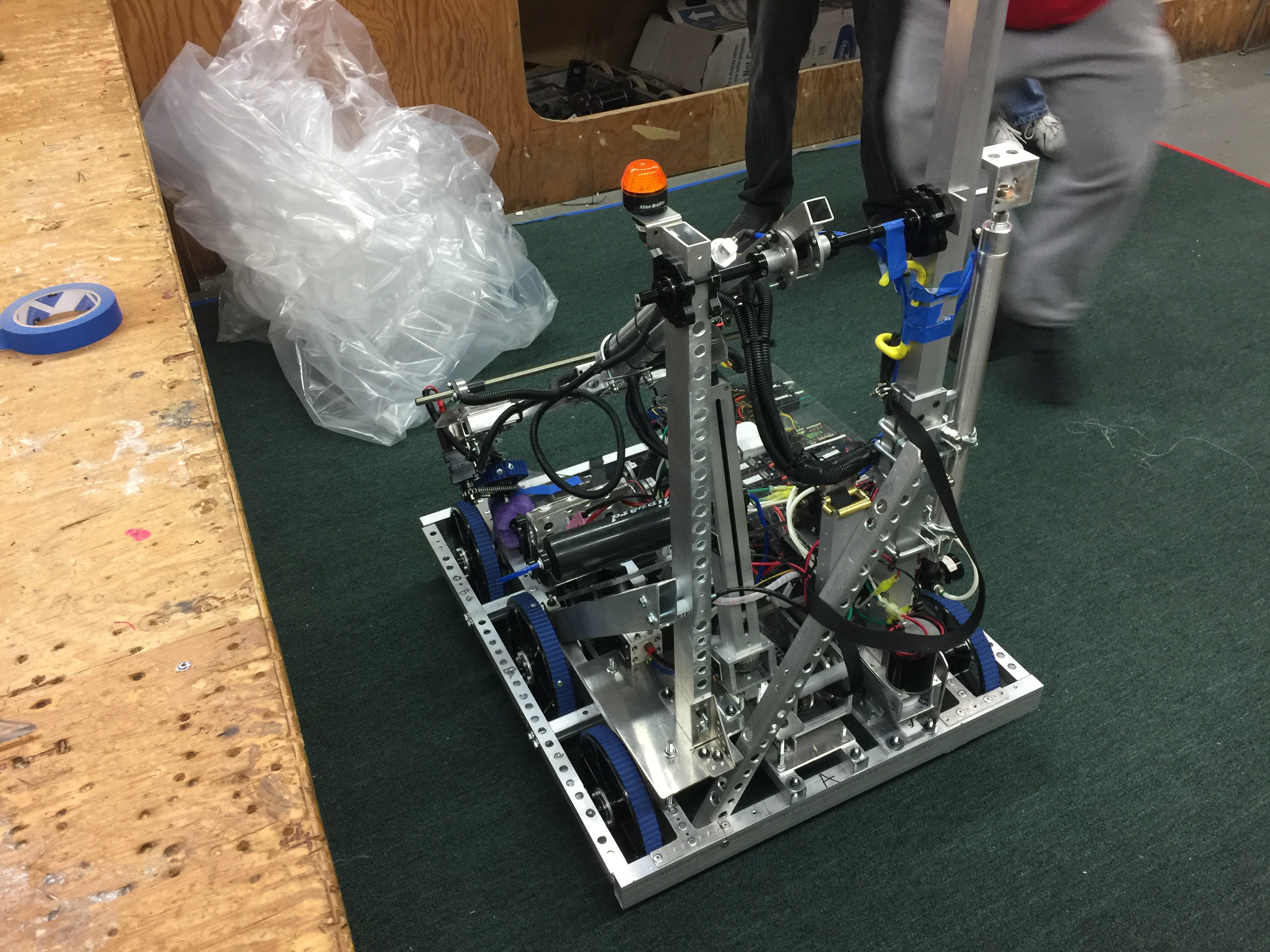

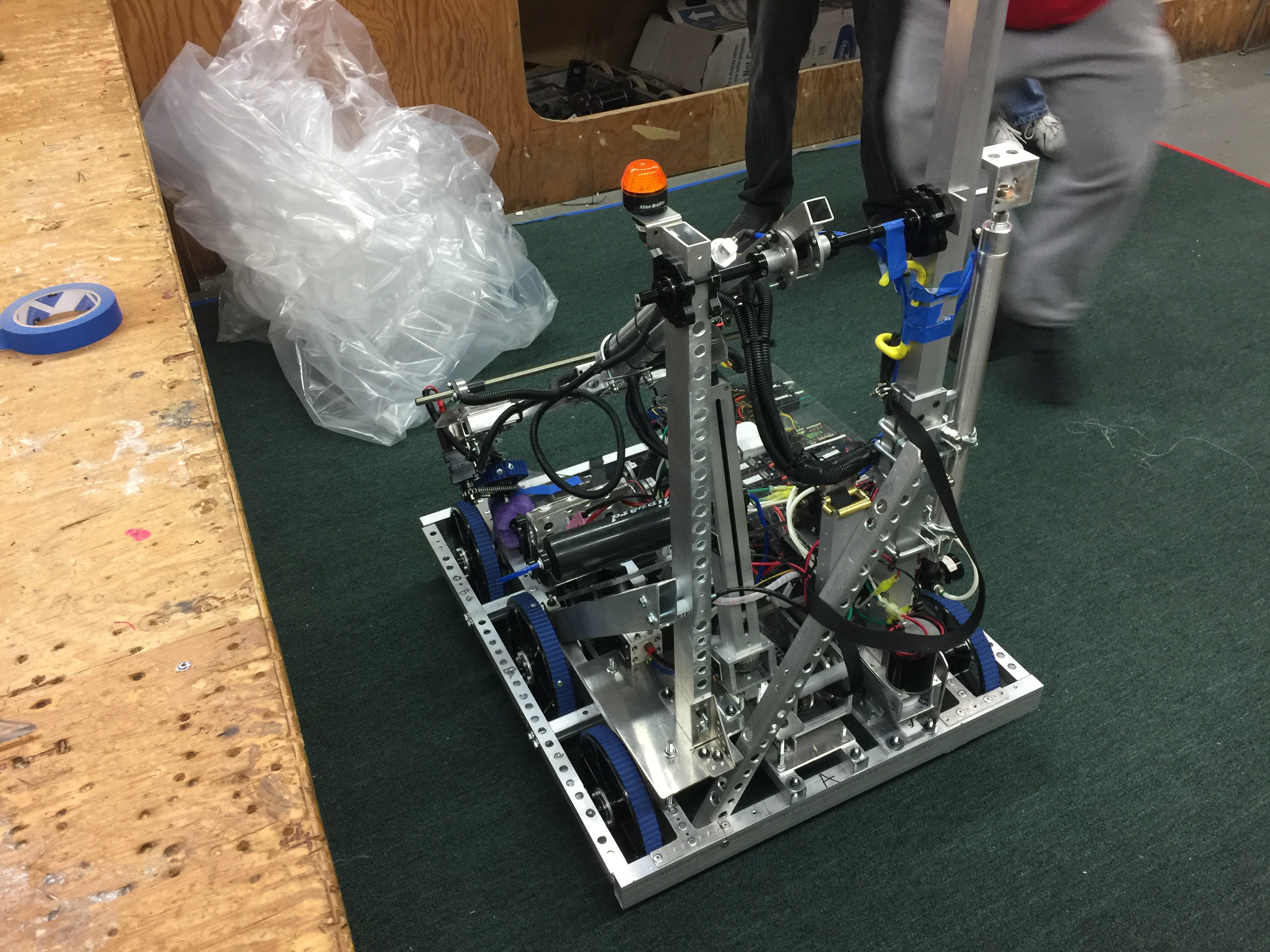

Introducing the ShortyBot, This bot was designed to perform in the FIRST Competition Stronghold. With the help of the members and mentors of TEAM 1635, this dream came true. We mainly focused on proficiency and the matter of competition. This robots most difficult part was building the custom tracks. We started off, by working in AutoCAD and SolidWorks, then we installed the design on the robot. In order to protect the wiring on the robot, we embed bent sheet metals. With numerous amounts of testing, and staying long hours at the workshop, this architecture became possible to build. TEAM 1635 can’t wait to take this bad boy at the competition. #Stronghold #TEAM1635 #FRC #FIRST

Edited and Produced By Jing Wei Li (Head Programmer of Team 1635)

Edited with Adobe Premiere Pro, Adobe Audition and Adobe After Effects

Music – Coldplay – Paradise (Instrumental)

This is a montage that showcases how Team 1635’s award-winning 2012 robot can cross the defenses of the FRC 2016 game.

Video Edited by: Li Jing Wei

The new members of Team 1635 getting to know each other and a little fun before the actual build season begins.

Video edited by: Li Wei Jing

Music – Walk The Moon – Different Colors

FOX News came to Newtown High School recently to conduct a new segment called ‘The Big Idea: Junior’. Our lead coach, Ms. Gonzalez very kindly prepared a series of questions in order to ensure we didn’t look completely dumbfounded at the startle of a camera. The morning that FOX came to our workshop the majority of us were pulled from class and given a few words by Mr. Paolino and Ms. Gonzalez. When the camera crew arrived we were told to act as we would any other day. Everyone was doing their assigned task whether it was working on tabs or working on the program. We used the practice robot we had instead of the actual robot we had built since we weren’t really supposed to take the official robot out of the bag. Dan Bowens interviewed around five members of the team: our Captain, Chrys, our head programmer, Li alongside Sade, our head designer Manish and myself. We were asked questions similar to those Ms. Gonzalez had anticipated. We were asked about our role in the team, the function of the competition and the function of the team in general. We were very excited and enjoyed having this experience.

This week was a combination of practicing and perfecting. Our driving team Chrys Sanchez and Manish Shretha maneuvered the controls to best complete the objective we needed. We practiced getting totes to and fro from their designated areas. We saw the various ways in which we could stack the boxes and in how many sets of them at a time. The team looked for the easiest and fastest way to get more done in a smaller period of time. Apart from this we also did a lot of troubleshooting, in the sense that we looked how to solve any problems that my come our way during competition. We checked how we would lift the can if it were on its side or even upside down. Overall, this was a week of problem-solving.

This week was particularly heavy for our programming department. This was the week in which we would test all of the functions and make sure that everything was working the way that it should. Our head programmer Li, alongside our mentor Bob led most of the testing on the robot. They ensured that the actuators were working at the same speed so that there would be no problem when trying to pick up totes and put them down. We didn’t want one actuator moving faster than the other, that would be unfortunate. Also during this week, we tested out our Autonomous. We had some difficulty in this department being that we got off to a rough start. However, by the end of the week, our programming team figured out the issue and made it run smoothly. Also towards the end of the week we got to do some practicing with a different school, Brooklyn Tech, they were kind enough to lend us some practice space. This week was quite a long one but in the end its where we made the most improvements on Midas.

Now that we had the prototype tested and knew that the model we built was going to work we started to make it out of metal. Like when building the prototype we gathered all the materials that we knew were necessary. Building the prototype made building Midas easier to construct because we already knew how the pieces were exactly supposed to fit. Again, we separated into groups so that we all did our designated jobs. Those who worked in electrical fixed up the wires and made things neater on the board so that the aesthetics of the board would be presentable. The mechanical team built the frame and claw into the robot. The programming team made some tweaks on how it is they thought the robot would drive best. By the end of the week we had assembled the robot and had some early practice.